To do work, the key advantages of chain blocks can not be overemphasized because labor is needed, in short, it is must-have lifting equipment for most companies. Several industries apply all forms of labor to do work; manual lifting of heavy materials causes a lot of strain which requires a lot of hands to be put to work. The revolution of how work is done has seen the invention of reliable, effective, and sophisticated machinery to do work. These types of machinery include hoisting systems in which chain blocks are incorporated to make lifting operations easier. They help companies reduce problems associated with lifting heavy materials and the cost of labor acquisition.

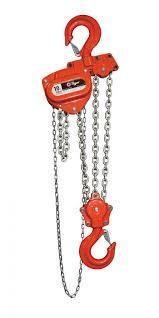

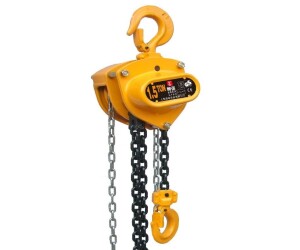

Chain blocks also known as chain hoists are fundamental parts of a hoisting system used for lifting heavy materials and machinery. They are reliable assets and ideal for companies using lifting equipment regularly, or currently completing manual lifts. When you want to lift and relocate heavy loads quickly, the most effective and comfortable option is to invest in chain blocks. It saves labor, time, and cost.

Chain blocks come in different sizes, depending on the magnitude of the job to be done. A chain block moves a load by pulling the hand chain attached to it. It comprises a hand-driven chain wheel with a non-load-bearing chain. The chain wheel drives a simple gearing mechanism that drives a sprocket wheel. The sprocket wheel carries the load chain. A hook or bottom block which is the point of contact with the material to be lifted is then attached to the load chain.

Chain blocks are used in several industries although, they are very common in construction sites, factories, shipyards, mines, and other industries. There are three types of Chain Blocks;

- Electrical or Pneumatic powered Chain Blocks

- Manual chain block

Chain blocks are made from high-grade steel (grade T) which is durable to ensure safety and reliability when lifting heavy loads.

The key advantages of chain blocks are endless, but the most important ones which make it a piece of must-have lifting equipment in the industry are listed as follows;

- Cost-effective:

Chain blocks are accepted widely because of their durability and ease to use; the entire equipment is safe and the performance is very high.

- Strength:

Chain blocks are strong and robust due to the material used to make them. The shell material of the equipment is made of high-quality alloy steel during the production process. Lifting heavy loads is a really big task, it is nearer to impossible in some cases. But the strength of chain blocks allows easy lifting of heavy loads without putting a high amount of effort.

- Easy Operation

Chain blocks have a compact shape, they are extremely lightweight and easy to handle which saves the time of mounting. Operating this equipment is easy and it can be operated by non-technical personnel with little training.

- Excellent working load limit:

Lifting tasks can be carried out effectively as chain blocks give you the ability to lift a very large load of over 50,000 kg. This makes it highly sort after.

- Simple structured design:

The design principle of chain blocks is quite simple which also makes them easy to repair and maintain.

Chain blocks are simple devices that give you massive mechanical benefits. The availability of chains block in your facility makes lifting loads very easy. It is a must-have for any company looking to cut down operational and labor costs.

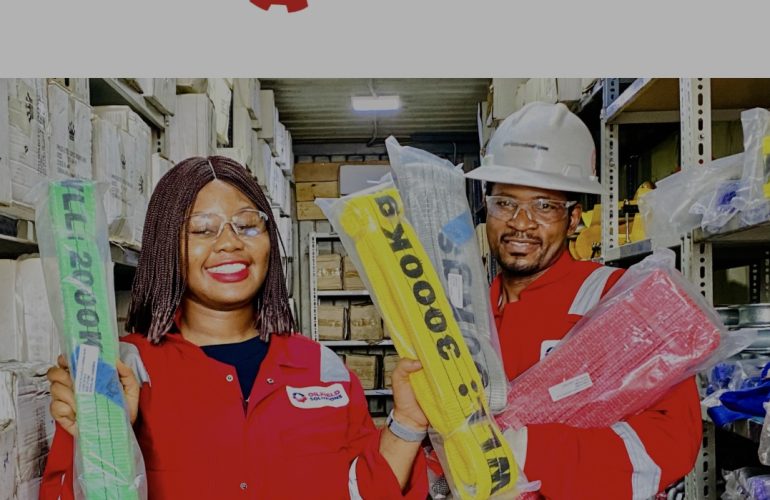

Are you in need of chain blocks to aid lifting operations? Contact us at 08076291657 or visit www.oilfieldsolutions-ng.com/lifting-equipment-supplies/

Oilfield Solutions Ltd is the largest Lifting Equipment Supplier in Nigeria. Our rigging shop holds a variety of lifting equipment to accommodate different needs as may be required in every lifting operation.