Structural Engineering

Why is OSL different? Our structural engineering team combines an in-depth understanding of the critical aspects of design, construction, and manufacturing process with knowledge of engineering principles, opportunities for technological and innovation – all of which are customized to our client’s end goals.

We have the breadth and depth of experience to tackle any structure our clients can conceive of, from conceptual design through to manufacture, commissioning and testing. Focusing on an engineer led approach, our structural engineers can create fully co-ordinated and integrated designs that not only ensure effective solutions but optimise the manufacturing

process and minimize maintenance costs along the way.

We are recognised for being a responsive, multi-disciplinary, and project focused company.

Our structural engineering capability can be utilised across a multitude of sectors including:

Decommissioning

- The best option for safe structural removal of fixed offshore structures and FPSOs whilst maintaining the highest standards of safety.

- Provide accurate weight reports and estimates for center of gravity (COG) for engineering lifts.

Brownfield Modifications

all the required structural engineering project functions such as:

- Constructions and fabrication drawings

- Onshore fabrication and compliance

- Redundancy modelling for existing structures

Asset Life Extension

- Remaining Life Assessment of ageing structures

- Fatigue assessment

- Identifying structural candidates for upgrades and modifications

Civil Construction

engineering projects majorly in:

- Detailed engineering design, CAD models, and construction drawings for civil structures

- Engineering studies into construction of major infrastructure projects

Start-up planning and commissioning

at the front-end, our responsibility is to provide engineering expertise to:

- Review and contribute to the Detailed Design of the mechanical deliverables

- Assist with all mechanical aspects related to equipment selection, design, installation,

commissioning, and start-up planning - Prepare and submit engineering progress data, including narratives, charts, and graphs.

- Prepare Inspection and test plans, including plans for Factory Acceptance Tests (FATS) and Site

Integration Tests (SITs) - Contribute to the development of an overall commissioning and start up logic and schedule,

to ensure seamless transition and handover from Construction to Commissioning and to

Operations.

To speak to someone in our structural engineering department today, E-Mail: bdm@oilfieldsolutions-ng.com

Why Choose Us

Quality Management System

Meeting and exceeding the expectations of our clients and stakeholders in compliance with ISO 9001:2015 is the core responsibility of every one of us at Oilfield Solutions. This has in turn guaranteed us repeat businesses while growing more customers through referrals.

Management Support

At Oilfield Solutions, we understand the importance of empowering our employees to achieving great success on projects. We accomplish this initiative through management support.

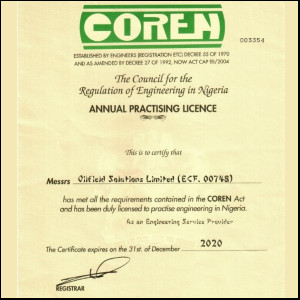

COREN License

As a brand with a long-standing history of compliance with regulatory bodies in the Industry, We are fully licensed by COREN upon exhibiting a proven demonstration of technical expertise. Therefore it is in our mandate never to compromise on quality service delivery to our clients and prospects.

Transparent Billing

Oilfield Solutions offer prices that are transparent and competitive. No hidden charges!

HSE Records

Oilfield Solutions maintains a proactive HSE Management System with Behavioural Based Safety Culture, evidenced by our impressive HSE KPI.

Regulatory Compliant

Working with Oilfield Solutions keeps you at peace from project stoppage due to non-regulatory compliance by companies in your value chain. We maintain our licenses validity, and relationships with the Industry Regulators.